- It takes 3.8Kg of oil to produce every new toner/laser cartridge.

- For inkjet cartridges, you require 85 grams of oil.

- One single toner cartridge emits around 4.8kg CO2 Greenhouse Gases per cartridge, this figure does not consider the toner inside

- Generally, a cartridge that yields five thousand pages contains 200 grams of toner, which means that the CO2 emission per cartridge is 3.2 kg.

- People can reduce landfilling when they recycle toner cartridges. Every remanufactured laser cartridge saves nearly 0,9 kg of metal & plastic waste from being deposited in landfills. Toner cartridge remanufacturing saves over 38,000 tons of plastic and metal from landfills.

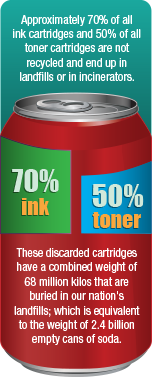

South Africa sells an estimate of 11 million cartridges every year and only about 30% of these are recycled. This means an alarming 70% end up in landfills. It takes anywhere from 450 to 1000 years for ink and toner cartridges to fully decompose. This is dependent on the plastic used. Some toners are made from industrial grade plastic thus increasing the time it takes to decompose.

Toner and ink cartridges that land up in landfills cause severe environmental damage as they leak toxic chemicals and hazardous waste materials into the soil, causing alarming damage to our ecosystem. Each ink cartridge produced carries a carbon footprint of 4.5kg of Carbon Dioxide (CO2).

Furthermore, the plastic they are made of is manufactured using an estimated two litres of crude oil per cartridge, which is a dangerous waste considering crude oil is a non-renewable resource. Making recycling even more important as this can save up to 40 million litres of oil every year.

A laser printer alone is responsible for around 45 kilograms of waste every year so if one-person reuses or recycles their used cartridges it saves an estimated 45 Kilograms of hazardous waste per year.